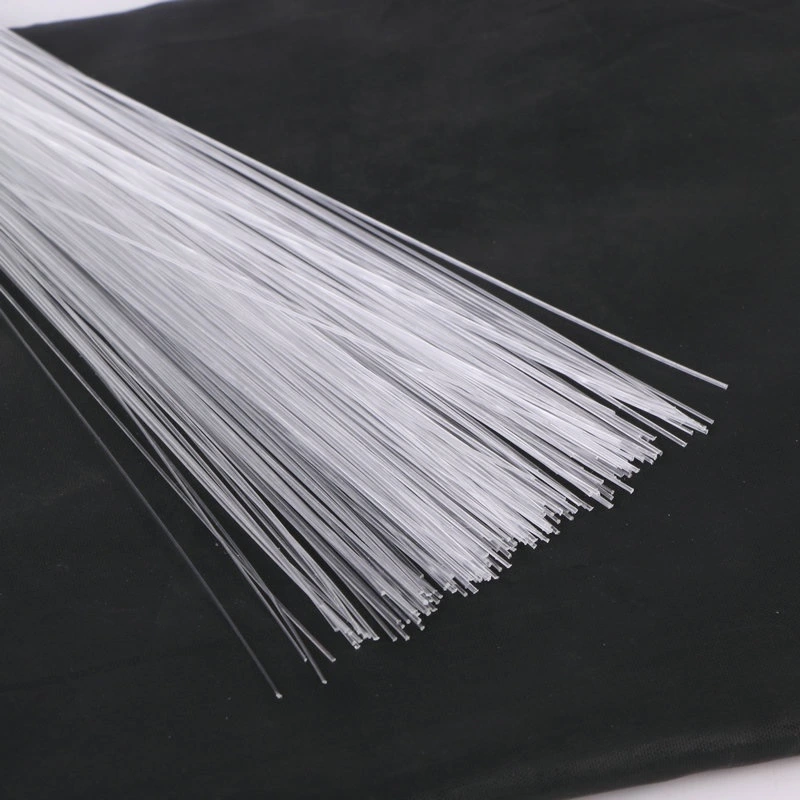

Preparation of raw materials

Choose high-quality plastic particles or other suitable raw materials to ensure that the materials meet production standards and environmental requirements. High quality raw materials provide a strong and durable foundation for the broom head, reducing problems caused by material defects during the production process and ensuring the quality and consistency of the final product.

Injection molding

Heat and melt plastic particles, then inject them into the mold through an injection molding machine and cool them into shape. The injection molding process ensures the precise size, consistent shape, and smooth surface of the plastic broom head. This process has high production efficiency and can mass produce high-quality broom heads to meet market demand.

Cooling and demolding

The plastic broom head after injection molding needs to be cooled and then removed from the mold. The cooling process ensures the shape stability of the plastic and prevents deformation. The size of the demolded broom head is stable, with good durability and usability, and is ready for subsequent processing.

Trimming and polishing

Trim and polish the cooled broom head to remove excess burrs and defects, making its surface smoother and smoother. The trimming and polishing process has improved the appearance quality of the product, ensuring that each broom head meets the aesthetic and usage requirements, and providing consumers with a good user experience.

Quality inspection

Strictly inspect the quality of the finished broom head, checking its size, shape, strength, and surface quality to ensure that each product meets the standards. The quality inspection process ensures product consistency and high quality, reduces the outflow of non-conforming products, and maintains brand reputation.

Assembly and assembly

Assemble and assemble the qualified broom head with the broom rod to ensure firm connection and flexible operation. The assembled broom undergoes final inspection to ensure that all parts are tightly connected and the overall structure is stable, providing users with reliable cleaning tools.

Packaging and Shipping

During the packaging and shipping process, each broom head is wrapped with protective materials and placed in a dedicated packaging box labeled with the production batch and date to ensure the safety and quality of the product during transportation. Warehouse management personnel arrange shipments based on orders and use logistics tracking systems to monitor product locations in real-time, ensuring that customers receive high-quality products quickly.